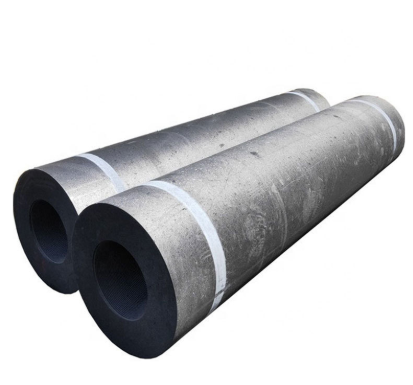

Ultra High Power Graphite Electrodes: The Key to Increased Steel Production

The material composition of the graphite electrode:

Graphite electrodes are mainly made of graphite material, which is a material with high electrical conductivity and corrosion resistance. Graphite electrodes are usually made by mixing and pressing graphite particles and binders.

The material composition of the copper electrode:

Copper electrodes are mainly made of pure copper, a metallic material with excellent electrical conductivity and mechanical properties. Copper electrodes are generally processed from pure copper materials.

Application method:

The application mode of graphite electrode is mainly as an electrode material for conducting electricity and transmitting electric current. It is commonly used as an anode or cathode in electrochemical reactions, in electrolytic cells in corrosive media, and as electrodes in electrical equipment.

Copper electrodes are also used as electrode materials, mainly for electrical transmission and conduction. It is widely used in electrical equipment, wires, terminals, cables, etc. in electrical engineering.

application:

Graphite electrodes are widely used, including electrochemical industry, metallurgical industry, chemical industry, etc. They are often used in electrolytic cells, electric furnaces, batteries and other equipment, and are also used in electrodes in corrosive media, such as acid-base solutions, redox reactions, etc.

Copper electrodes are widely used in the electrical industry, including power generation, transformation, transmission, and power equipment. Copper electrodes are also suitable for electric welding, refrigeration equipment, machining and other fields that need to conduct current.

the difference:

Conductivity: Both graphite electrodes and copper electrodes have good conductivity, but copper electrodes are more conductive. Therefore, copper electrodes are generally preferred where high current transfer is required.

Corrosion resistance: Graphite electrodes have excellent corrosion resistance and can operate stably for a long time in acid-base solutions or high-temperature and high-pressure environments. Copper electrodes have better corrosion resistance to some specific corrosive media, but are not as good as graphite electrodes in comparison.

Mechanical properties: Copper electrodes have high mechanical strength and hardness, and can withstand greater pressure and stress. In contrast, graphite electrodes have poor mechanical properties and are easily damaged.

Lifespan: Since copper electrodes have better corrosion resistance and mechanical properties, they generally have a longer lifespan. Graphite electrodes have a relatively short lifetime.

Cost: Graphite electrodes can in some cases offer better cost-effectiveness than copper electrodes, which are less expensive to manufacture.

Advantages of graphite electrodes include:

Good conductivity: Graphite electrodes have good conductivity and can effectively transmit electric current.

Corrosion resistance: Graphite electrodes have good corrosion resistance to various chemical substances and can be used for a long time in some corrosive environments.

Lightweight: Compared with copper electrodes, graphite electrodes have a lower density, making them lighter and more convenient to use in some occasions.

Wide range of applications: graphite electrodes can be used in different industries and fields such as electrochemistry and metallurgy.

Cost-effective: Graphite electrodes are cheaper to manufacture than copper electrodes and thus can offer better cost-effectiveness in some cases.

Advantages of copper electrodes include:

Good conductivity: Copper electrode is an excellent conductive material with high conductivity and can provide stable current transmission.

Mechanical strength: Copper electrodes have high mechanical strength and hardness, and can withstand high pressure and stress.

Plasticity: copper electrodes can be processed into various shapes and sizes, easy to adapt to various needs.

High temperature stability: Compared with graphite electrodes, copper electrodes have better stability and reliability in high temperature environments.

Long life: Copper electrodes have a longer life than graphite electrodes and are less prone to wear and damage.

Graphite electrodes can replace copper electrodes for the following reasons:

Physical properties: Graphite electrodes have good electrical and thermal conductivity, can effectively transmit current and dissipate heat, so they can be used as electrodes.

Chemical stability: Graphite electrodes have good corrosion resistance under various chemical substances, and can work stably for a long time without being corroded.

Cost-effective: Graphite electrodes are cheaper to manufacture than copper electrodes, so using graphite electrodes in some applications can reduce production costs.

Plasticity: Graphite electrodes can be manufactured into various shapes and sizes according to needs, so it is suitable for different electrode designs and application requirements.

Recent Posts

undefined

Quote Now

Quote Now